One of the best brake discs that we can find are the ceramic brakes. Its qualities are far above the conventional brakes that most cars carry.

Among its and advantages are: its greater resistance, a lower weight and great durability. Although there are many other virtues that most are unaware of. As for his disadvantages, apart from its high cost, which means that we only see them in some sports cars, there are also some other cons that make more than one regret having bought it.

types of brakes

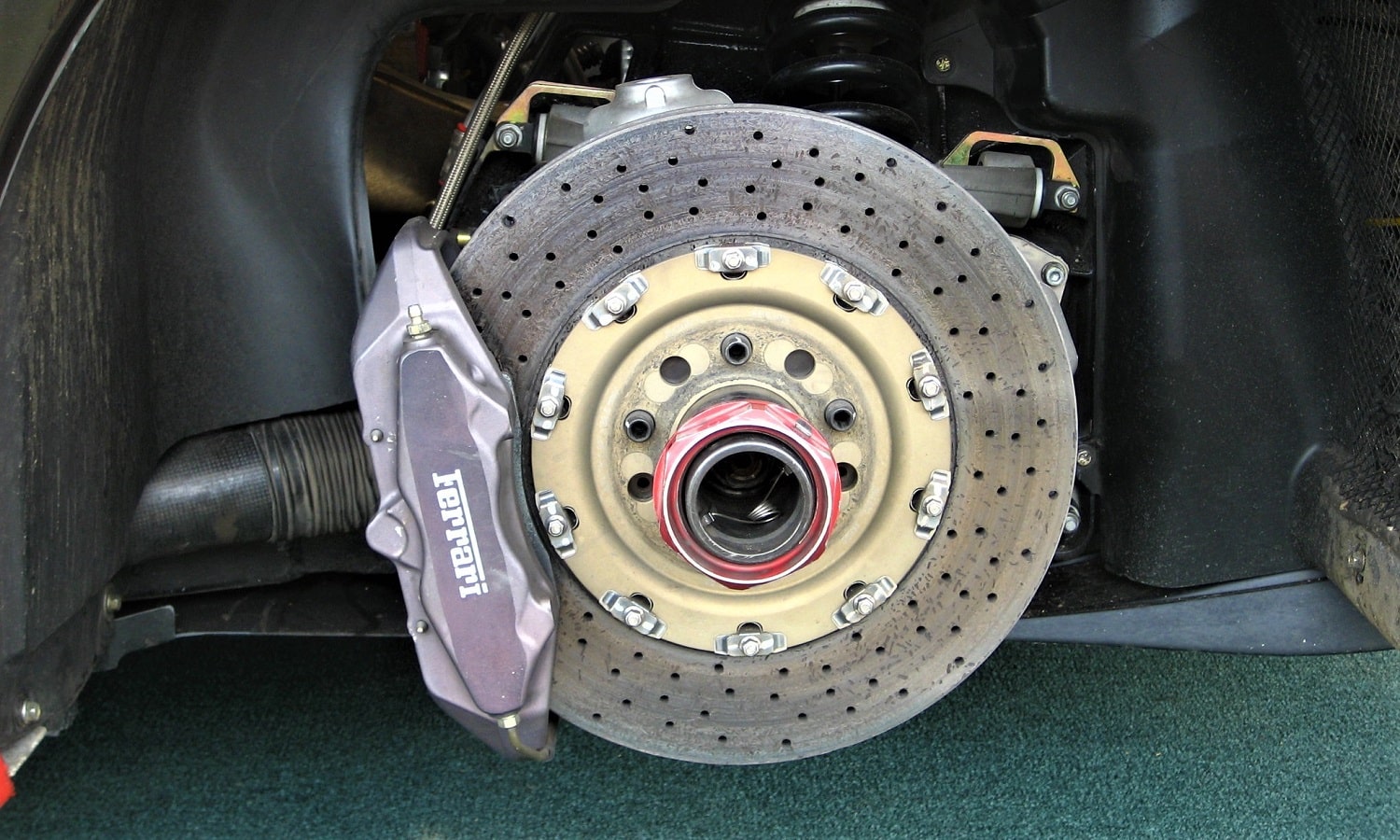

A disc brake is essentially made up of the caliper and disc pads. A brake disc it is a fairly simple implement. Its function is to transform the kinetic energy of the linear movement of the car into heat when it is held by the caliper and the brake pads (through friction). The material used for the construction of a disc must have the ability to absorb and dissipate heat, while having sufficient mechanical resistance to withstand the clamping force of the caliper and the braking torque. It also needs to transmit a proper and controllable amount of friction when interacting with the brake pads.

In the manufacture of brakes there are three types, although in this article we will focus on two of them:

- Metallic, made of solid iron.

- Carboceramics or ceramics (composed of a ceramic matrix)

- Pure carbon (used in competition)

Advantages of ceramic braces

It is well known that the performance of ceramic brakes is superior to that of steel. It does not matter if they are perforated, scratched or other designs to improve their capabilities, ceramics will always be far above.

Their main quality is that they have a higher temperature resistance, so they show no signs of being exhausted under heavy use. That is why it is practically impossible for them to warp due to a very sudden thermal shock. Hence, it is equipped with cars designed for the circuit, supercars or, as an extra, in high-performance cars. You can see ceramic brakes in action in the Audi RS3 Sedan test:

For this reason, and for other properties of its material, it also are more durable than conventional brakes. So much so, that it is often said that they last more than 300.000 km. However, this figure is misleading because, depending on how it is used and the type of car it is, its duration can be greatly reduced. In addition, we are not even talking about 300.000 km on the circuit, but rather with normal driving.

As an addition, its weight is half that of the steel ones. Which brings another extra advantage to the sports cars that carry them, which precisely need to reduce their weight as much as possible. This advantage is even more accentuated in some cases, because some brands use lightweight materials such as aluminum or titanium to reduce the weight of other parts of the brake.

ceramic brakes too can reduce stopping distances in some cases. Although this is mainly so because they lose much less braking power when heated.

The advantage that most are unaware of has to do with the environment. ceramic braces produce much less fine dust when operating. Very small particles that remain suspended in the air and that affect people's health and even reduce their life expectancy.

Disadvantages of ceramic braces

You will see that this list is much shorter than that of the advantages, but do not forget that ceramic braces also have their counterparts. The first and most obvious is the price, which is much larger than that of normal brake discs.

The downside that some buyers are unaware of when choosing to mount ceramic brakes is that they squeak with some frequency. A sound that can be somewhat annoying in cars that are used for something other than racing. For example, in the RS line from Audi or the M models from BMW.

What are ceramic braces made of?

Although they are often called ceramic braces for simplicity, it is more correct to call them ceramic composite discs. The word composite refers to the fact that the ceramic material, silicon, is combined with carbon fiber to increase its resistance. Hence they are called also carbon ceramic brakes.

To be more exact, the carbon fiber is compacted to a great extent, but it leaves some pores through which the molten silicon carbide enters, creating a ceramic matrix inside. The result is an extremely hard compound that is resistant to abrasion and temperature.

how they are made

To create the interior of the ceramic discs carbon fiber is mixed with a resin, it is put into disc-shaped molds and it compacts with a press with a force of 20 tons while heated to 200ºC. With this, the carbon fiber is compacted and the resin becomes plastic.

After cooling the discs, rough parts are removed and ventilation holes are made, to immediately heat them again in an oven for two days. Over there its temperature will rise to 1.000 degrees progressively to produce a chemical alteration that converts the plastic into carbon.

The next step is add fine silicon powder to disc and put it back in the oven for another 24 hours. Over there will gradually heat up to 1.700ºC, to melt fine silicon powder into silicon carbide. An extremely hard material that seeps through the micropores of the disc.

Now is the time to do some extra holes on the inside, which is where the necessary cup will be inserted to be able to mount them. Later, a layer of protective paint is added to isolate carbon from oxygen in the atmosphere. A crucial step, which prevents oxygen from allowing carbon to burn at high temperatures. The paint is cured in another oven, leaving behind a white powder.

Lastly, a robot polishes the surface of the discs and a camera analyzes the disc at a microscopic level to ensure there are no blemishes. Once this quality check is complete, the cup is added so that it can be mounted on the car. As you can see, it is a long process in which all the steps added together exceed a week to manufacture a batch of discs.

This type of material is called Carbon Fiber-reinforced Silicon Carbide (C-SiC), whose translation into Spanish is Carbon fiber reinforced with Silicon Carbide.

Types of ceramic braces

As with many systems and inventions in the motor world, each brand gives it a different name as part of your marketing campaign. However, in many cases the essential differences between one and the other are minimal or non-existent in terms of their operation and construction.

That's the case with ceramic brakes, which go by names like Ceramic Composite Material (CCM), Ceramic Matrix Composite (CMC) or Carbon Ceramic Brakes (CCB). Even more specific names that include the brand like Porsche Ceramic Composite Brakes (PCCB). But, in essence, we are dealing with the same type of brakes based on the technology described above: Carbon Fiber-reinforced Silicon Carbide (C-SiC).

The type of brakes with which not to be confused with Carbon-Carbon (C/C) brakes. They are used in aeronautics, railway transport and the F1, because they are even more resistant. However, its optimum operating temperature is too high to put on street car brakes. As the name suggests, they are not ceramic brakes because they only have carbon treated in a very specific way, which takes even longer to manufacture.

Is it worth putting ceramic braces?

the brakes are one of the most important elements of our car that belong to active safety. Good brakes allow us to stop the car sooner and, depending on the case, avoid a possible accident. So, according to this reasoning, ceramic braces will be a good decision if you have a budget. However, this does not have to be like this.

Given its qualities, it only makes sense put ceramic brakes on a car if it is going to be used very intensively. That is, running on a circuit and practicing driving that with other weaker material would cause the discs to overheat. An extreme situation that usually only occurs in competition or in very demanding circuit batches.

price of ceramic braces

The most affordable in production cars are the models that can be equipped as an extra for about 10.000 euros. Although this outlay usually includes pieces of more pistons, modifications to the chassis to improve its dynamic behavior and some aesthetic details.

If we go to the other extreme, one of the most expensive things in street cars are the Bugatti Chiron's carbon-ceramic brake discs. Replacing them along with the 3D printed titanium pads and calipers costs more than 50.000 euros.

Botton line

Ceramic brakes are made of carbon fiber reinforced ceramic. This ceramic composite, together with silicon carbide, offers great resistance to abrasion, as well as providing great hardness.

The origins of ceramic brakes come from airplanes and also from competition, offering very good results. This type of brakes are characterized by having a very good resistance to fading and, in addition, they can last up to four times longer than conventional steel brakes.

The temperature that the brakes can reach when we use them is 700ºC, reducing its effectiveness. Fortunately, ceramic brakes do not have this problem and are capable of distributing heat over the entire surface of the disc.

Regarding the weight of the ceramic brakes, it can be said that they are much lighter than the conventional ones. This type of brakes can weigh half as much, which provides us with significant weight savings.

However, not all are advantages in ceramic brakes. These brakes have a very high price, making them very exclusive and only sports cars from brands like Ferrari or Porsche equip this type of brakes to their vehicles. The cost of this type of brakes can exceed $9.000.

The manufacture of a ceramic brake disc is much slower than that of a normal one, and can take almost a full day to make a single disc.

The service life of ceramic brake discs can reach 300.000 kilometers. Therefore, in many cases, these types of brakes will not need to be replaced throughout the life of the vehicle.

Pictures – twin-loc, Andy Durst, Travis Isaacs, Yahya S., The359, Ben Ramirez, Bill Abbott, Razvan Orendovici